Use these 7 Effective Tips to improve your supply chain Optimization gain better cost efficiency and quality in production and distribution.

Supply chains are facing challenges and changes globally, leading to increased complexity in supply chain management. It’s crucial to carefully manage and prioritize supply chain optimization now more than ever.

What is supply chain optimization?

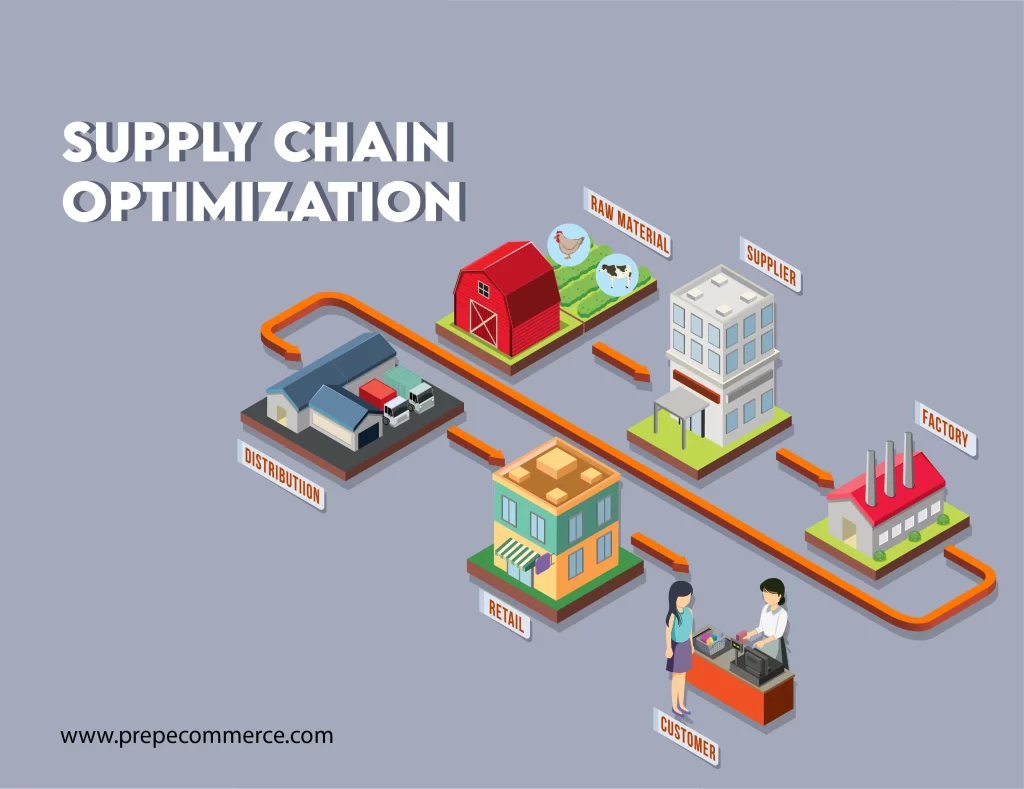

Before getting started with discussing the topic of optimization you need to own a clear understanding of the process that is being used by companies to turn the raw materials into saleable products.

The practices and techniques used for the below-mentioned topics refer to supply chain management (SCM) :

1. Procuring goods and services

2. Providing high-quality products and services

3. Distributing those products for sale

Below we’ve talked about a few examples of modern supply chain management activities:

• Through the procurement process requisitioning supplies

• Establishing manufacturing timelines and parameters

• Administering inventory control and capacity planning

• Interrelating warehousing and logistics activities

• For downstream partners create distribution plans

Supply chain optimization means making all of these activities and business processes more efficient.

The main purposes for optimizing the supply chain are:

• Save money

• Eliminate cash leaks

• Amplify the product quality

• Distribute goods efficiently

• Quick response to changing market and economic conditions

Why is it important to optimize the supply chain?

To ensure that your organization is capable of maintaining a competitive advantage in production and distribution products, you’ll need to optimize the supply chain. If the supply chain is poorly managed then it’ll result in being costly and inefficient. Also, it becomes more susceptible to developing business risks, like quality issues, inventory shortages, production, and fraud of supply.

Implementing highly efficient supply chain operations business can generate improved results in various ways:

1. Reducing silos of information: Managing the supply chain is a collaborative process. Within an organization, as part of a larger ecosystem, SCM operates. Supply chain management becomes less effective and more prone to issues with siloed information. Whereas with a well-designed supply chain process, all stakeholders are provided with the access they need to complete their assigned duties effectively.

2. Facilitate accurate planning: The planning of an effective supply chain depends completely on the capability of the organization to imagine the future. Supply chain teams can make better decisions by having a clear and transparent process where all relevant data are effectively surfaced. They are capable of implementing more precise production schedules, capacity plans, demand planning, forecasts, and budgets.

3. Fast response time: The overall agility of production and distribution relies solely on visibility and planning. With optimization of the supply chain processes, the teams working can implement solutions with accuracy and speed to unforeseen issues.

4. Reduction of risks: Business risks are various like supply chain disruption, data breaches, production delays, and delivery exceptions; all of these can be reduced or eliminated through advanced supply chain optimization. High-risk issues appear less common because excellent supply chain optimization establishes a framework for vendor assessment, due diligence, and tracking.

5. Utilize Technology and Automation: To streamline the processes, reduce errors, and improve efficiency, you would be required to invest in supply chain management software and automation tools. For real-time tracking of demand forecasting, inventory, predictive maintenance, and enabling proactive decision-making, use technologies like RFID, IoT sensors, and AI.

6. Get Associated with Partners and Suppliers: Establish an enduring connection with distributors, suppliers, and logistical partners. This is required to optimize processes, coordinate activities, and share information. To improve overall supply chain responsiveness, minimize stockouts, and reduce lead times, you should implement vendor-managed inventory (VMI) and joint planning.

7. Apply Lean Principles: To enhance production efficiency, reduce excess inventory, and eliminate waste, apply lean manufacturing principles. To optimize workflows, shorten cycle times, and improve resource utilization ensure implementation of practices such as Just-in-Time (JIT) inventory management, Kanban systems, and value stream mapping.

Crucial Components for Efficient Supply Chain Optimization

Based on the organization and its goals, the supply chain management (SCM) strategy varies from one business to the other. We’ll know that every business is different from the other and follows a slightly different strategy, but some key features of the supply chain practiced are:

1. Precise Transparency of Supply Chain- Through well-designed supply chain processes, a detailed picture of planning and manufacturing activities in real-time is provided to stakeholders throughout an organization. Thus, the cooperation of stakeholders and data transparency is further intensified.

2. Management of orders- For every business, clients are the heart of revenue, so always ensure that supply chain management pays added and effective attention to the orders of customers. The ability to track, capture, fulfill, and manage customer orders is a feature that is included in a well-designed supply chain management process. If you make use of tools to meet their expectations and experience, they’ll feel more confident and loyal.

3. Control of inventory- One of the most vital aspects of managing the supply chain is the effective management of supplies, materials, and finished products. Therefore, to ensure operational efficiency, a first-class SCM function will include sophisticated, technologically enabled ways for tracking and maintaining inventory levels.

4. Reporting and Analysis- All alternate optimization strategies are based on the principle of efficient data utilization. In an attempt to deliver the most precise and thorough planning, a highly optimized supply chain will utilize external data, evaluations, historical and current internal data, and trend reporting. You can achieve improved outcomes and every risk is reduced with a proper understanding of supply chain data.

5. Sustainability- Recently, impact-focused supply chain management has become the primary focus of any industry. Streamlining the supply chain allows departments to focus more on ensuring sustainability throughout the entire supply process. This can result in improved business results and increased customer loyalty from those who view sustainability as essential to their relationship with the brand.